The Mechanics Behind Cotton Picker Machines: An In-Depth Look

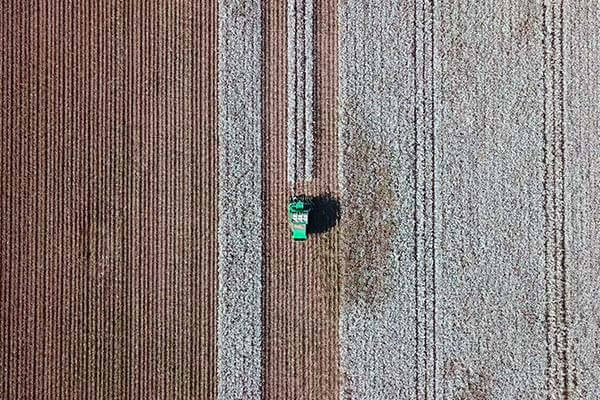

In the world of agriculture, efficiency and productivity are the keys to success. One of the most revolutionary advancements in farming technology is the cotton picker machine—a powerful and intricate piece of equipment designed to harvest cotton quickly, efficiently, and with minimal labor. At Certi-Pik, USA, we specialize in manufacturing high-quality replacement parts for cotton picker machines, ensuring they run smoothly and effectively season after season.

But how exactly does a cotton picker machine work? What makes it so efficient, and what components are essential to its operation? In this in-depth guide, we’ll explore the mechanics behind cotton picker machines, breaking down each component and explaining how it contributes to the overall functionality and efficiency of the machine. By the end, you’ll have a comprehensive understanding of how these incredible machines work and why they’re indispensable in modern cotton farming.

If you’re a cotton farmer, equipment operator, or simply curious about agricultural technology, you’re in the right place. Let’s dive into the mechanics of the cotton picker machine and discover the science behind its impressive performance.

The Evolution of Cotton Picker Machines

Before we delve into the mechanics, it’s essential to understand how cotton picker machines evolved from manual labor to the advanced, high-tech machines we see today.

1. From Manual Labor to Mechanization

In the early days of cotton farming, cotton was picked by hand—a labor-intensive and time-consuming process. Workers manually plucked cotton bolls from the plants, requiring a significant workforce and long hours. This traditional method was not only inefficient but also costly for farmers.

2. The Birth of Mechanical Cotton Pickers

The first mechanical cotton pickers emerged in the 1930s, revolutionizing the cotton industry by significantly increasing productivity and reducing labor costs. These early machines used rotating spindles to pick cotton bolls while leaving the plants intact.

- John Daniel Rust: Invented the first commercially successful mechanical cotton picker in 1936, utilizing spindle technology that became the foundation for modern cotton pickers.

- Spindle Technology: Rust’s design featured rotating spindles that gently pulled cotton fibers from the bolls, minimizing fiber damage and maintaining the integrity of the plants.

3. The Rise of Modern Cotton Picker Machines

Today’s cotton picker machines are sophisticated, high-tech marvels of engineering, capable of harvesting vast fields of cotton with remarkable speed and efficiency. Key advancements include:

- Increased Harvesting Speed: Modern machines can harvest multiple rows of cotton simultaneously, maximizing productivity.

- Precision and Efficiency: Advanced spindle technology ensures precise picking without damaging the cotton fibers.

- Automated Controls and GPS Integration: Automation and GPS technology allow for accurate navigation, efficient operation, and reduced operator fatigue.

Certi-Pik, USA’s Role in the Evolution

At Certi-Pik, USA, we’re proud to support the evolution of cotton picker machines by manufacturing high-quality replacement parts that enhance performance, durability, and efficiency. We understand the importance of reliable equipment in maximizing productivity and profitability for today’s cotton farmers.

How Cotton Picker Machines Work: The Core Components

A cotton picker machine is a complex piece of equipment with multiple components working together to efficiently harvest cotton. Here’s an in-depth look at the core components and how they function:

1. Picking Units

The picking units are the heart of the cotton picker machine, responsible for harvesting the cotton bolls from the plants. Each picking unit contains the following key components:

- Spindles: Rotating spindles are thin barbed metal rods that spin rapidly, catching the cotton fibers and pulling them from the bolls. They are designed to:

- Minimize Fiber Damage: Calibrating you cotton harvester for crop and weather conditions is essential in ensuring minimal damage to the cotton. Keeping your components in good condition and set to proper clearances helps the spindles do their jobs.

- Maximize Efficiency: Multiple spindles rotate simultaneously to maximize the picking rate. Efficiency is only as good as the spindles used so in addition to installing quality parts: be sure to replace broken or worn spindles as needed.

- Doffers: Doffers are rubber disks that remove the cotton from the spindles and direct it into the air suction system.

- Efficient Removal: They efficiently strip the cotton from the spindles by rotating opposite the direction of the spindles, preventing clogs and maintaining a steady flow when correct clearances are set.

- Durable and Reliable: High-quality doffers are designed to withstand constant friction and pressure.

- Moistening System: A water-based moistening system keeps the spindles lubricated, preventing cotton from sticking and reducing friction. When using our proprietary moistener pad water distribution pattern you can be assured your spindles will be lubricated in the most efficient manner possible.

2. Air Suction and Conveyor System

Once the cotton is removed from the spindles, it’s transported through the machine using a powerful air suction and conveyor system:

- Air Ducts and Fans: High-speed fans create powerful air suction that moves the cotton from the doffers to the basket. Sometimes overlooked, but of extreme importance in maintaining efficiency is to reduce air gaps in duct work and cabinet components that reduce the suction needed to move the cotton through the picker.

- Conveyor Belts: Conveyor belts transport the cotton through the machine, ensuring smooth and efficient movement.

- Lint Cleaners: Advanced lint cleaners in cotton strippers remove debris, dirt, and leaves, ensuring that the harvested cotton is clean and high quality.

3. Basket and Module Builder

The harvested cotton is collected in a basket, where it is compressed into modules for easy storage and transportation:

- Basket Capacity: Modern cotton picker machines feature high-capacity baskets that hold large volumes of cotton, reducing the need for frequent unloading.

- Module Builder: Some models have built-in module builders that compress the cotton into compact, uniform modules, making it easier to transport and store.

- Automated Unloading: The automated unloading system in module builders simplifies the process of transferring modules from the harvester to the staging area as they are awaiting ginning.

4. Engine and Power System

Cotton picker machines are powered by high-performance diesel engines designed for durability, fuel efficiency, and reliability. They provide the power needed to operate the:

- Picking Units

- Air Suction System

- Conveyor Belts and Module Builder

- Hydraulic Systems for steering, lifting, and unloading.

Certi-Pik, USA’s Expertise in Replacement Parts

At Certi-Pik, USA, we specialize in manufacturing and supplying high-quality replacement parts for cotton picker machines, including spindles, doffers, cam tracks, moisture pads, and more. Our parts are designed to maximize efficiency, durability, and performance, ensuring that your cotton picker machine runs smoothly and efficiently.

Certi-Pik, USA Tip: Regular maintenance and high-quality replacement parts are essential for maximizing the performance and lifespan of your cotton picker machine. Let us know if you have any issues that you are working through with your cotton harvester that require a new solution to improve your time spent harvesting.

Why Choose Certi-Pik, USA for Cotton Picker Parts?

At Certi-Pik, USA, we’re dedicated to supporting cotton farmers with high-quality, reliable, and durable replacement parts for cotton picker machines. Here’s why you should choose us:

- Unmatched Quality and Durability: Our parts are manufactured using premium materials to ensure long-lasting performance.

- Comprehensive Selection: We offer a wide range of replacement parts for John Deere and Case IH cotton pickers, including spindles, cam tracks, doffers, and more.

- Expert Knowledge and Support: With decades of experience in the cotton industry, our team provides expert guidance and support to help you find the right parts for your needs.

- Commitment to Innovation: We stay up-to-date with the latest advancements in cotton picker technology to deliver cutting-edge solutions.

- Customer Satisfaction and Trust: Our commitment to quality, reliability, and customer satisfaction has made us a trusted name in the cotton industry.

The Certi-Pik, USA Promise

We believe in empowering cotton farmers with the tools and resources they need to succeed. Our mission is to provide high-quality products, exceptional customer service, and unbeatable value. At Certi-Pik, USA, we’re dedicated to helping you keep your cotton pickers running smoothly and efficiently, season after season.

Ready to Optimize Your Cotton Picker Machine? Contact Certi-Pik, USA Today!

If you’re looking for high-quality, reliable replacement parts for your cotton picker machine, look no further than Certi-Pik, USA. Our extensive selection, competitive pricing, and expert guidance make us the go-to choice for cotton farmers nationwide.

Contact us today to explore our selection of cotton picker parts and find the perfect solution for your needs.