Reliability, durability, and performance are critical in agricultural machinery. Few brands embody these traits as consistently as Case IH, a long-standing leader in the field of farming equipment. Whether you’re managing a small farm or operating a large commercial agricultural enterprise, ensuring your machinery performs at its best is vital to your productivity, and the

READ MORECotton Picker Parts

What Are the Main Parts of a Cotton Harvester?

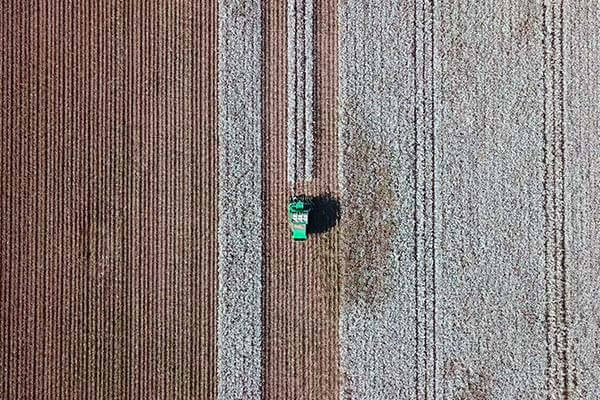

Cotton harvesting is a critical stage in the agricultural process that requires specialized machinery to ensure efficiency and minimize crop loss. Cotton harvesters, whether spindle pickers or stripper harvesters, are complex machines with numerous components working together to gather, clean, and store the cotton crop. Farmers and technicians must understand the main parts of a

READ MOREThe Role of the Cotton Picker Spindle: Why Quality Matters in Harvest Efficiency

The cotton industry depends on machinery that can reliably perform in rugged field conditions while delivering high yields with minimal fiber damage. One of the most critical components in this process is the cotton picker spindle. These rotating components do the essential job of extracting cotton from the plant’s bolls. Though small compared to other

READ MOREThe Mechanics Behind Cotton Picker Machines: An In-Depth Look

In the world of agriculture, efficiency and productivity are the keys to success. One of the most revolutionary advancements in farming technology is the cotton picker machine—a powerful and intricate piece of equipment designed to harvest cotton quickly, efficiently, and with minimal labor. At Certi-Pik, USA, we specialize in manufacturing high-quality replacement parts for cotton

READ MOREIs Cotton Still Picked by Hand? A Look at Modern Mechanization and Its Impact on Farming

Cotton has been a vital agricultural crop for centuries, playing an essential role in economies and industries worldwide. Historically, the process of picking cotton was labor-intensive and often performed by hand, but advancements in agricultural technology have dramatically transformed the industry. Today, the question arises: is cotton still picked by hand? The answer largely depends

READ MORE