The cotton gin is a machine that was designed to streamline the separation of fibers from their seeds. It enabled higher productivity levels than the manual separation that had been used up until that time.

The effects of this invention extended far beyond the field and into the entire world, with surprising ramifications that still affect us today.

When Was the Cotton Gin Invented?

The earliest version of the cotton gin was a single-roller mechanism that extends as far back as the fifth century in western Indian. These early gins were difficult to use and required a great deal of skill.

The single-roller gins continued to be used for centuries, eventually being replaced by a two-roller version in India and China sometime between the 12th and 14th centuries.

The new and improved two-roller mechanism was known as the “wooden-worm-worked roller,” also called churka or charkha. This two-roller version was in common use throughout the Mediterranean trade by the 16th century, sometimes using water as its source of power. The churka is still used in the subcontinent of India to this day.

The Indian roller mechanism continued to thrive and was brought to the United States in the mid-18th century. It was quickly found to work well for cleaning long-staple varieties but not short-staple varieties, both of which are still grown in the South.

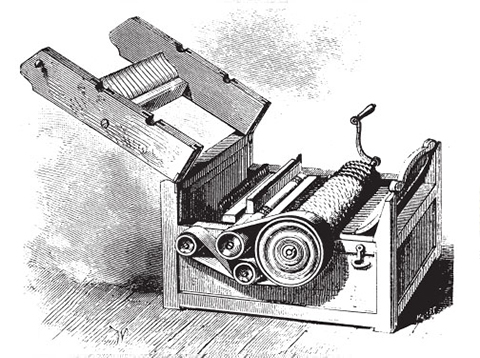

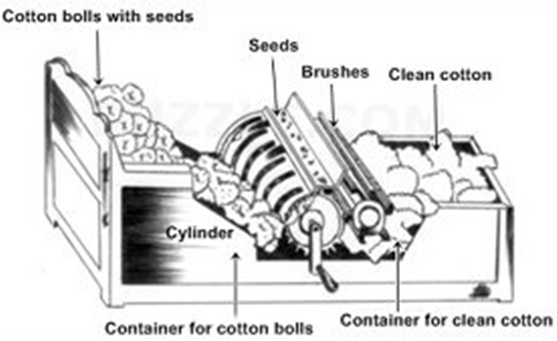

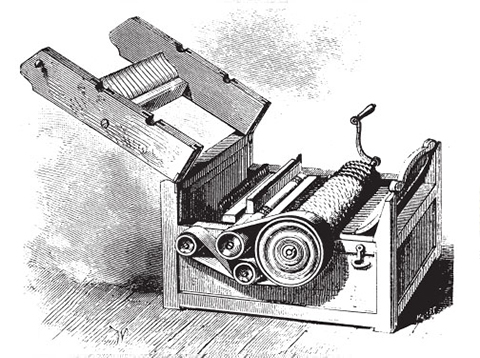

The American inventor Eli Whitney is responsible for inventing the machine that would successfully process short-staple material in 1793. His process, however, damaged extra-long-staple varieties. He was granted a patent for his invention, called the saw gin, the following year.

Understanding the Challenges

Cotton could be easily grown, and its fibers could be stored for a long time, unlike food crops. So, in many ways, it was an ideal crop. The challenge came in separating the seeds from the soft fibers. This is not an easy process.

Fibers are produced in the seed pods, or “bolls”, of the plant where the fibers, otherwise known as “lint”, in the bolls are tightly interwoven with seeds. The seeds and fibers must first be separated to make the fibers usable.

Additionally, the short-staple version was more labor-intensive, as it had to be painstakingly hand-cleaned, one plant at a time. The average rate for removing seeds by hand was only about one pound per day.

The long-staple variety was easy to clean but only grew well along coastal areas, so that crop was necessarily limited in scope.

What Does It Do?

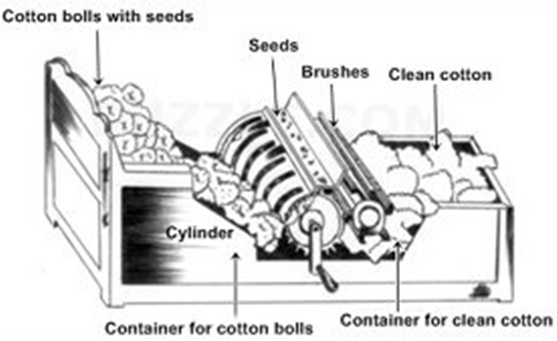

The cotton gin, the word “gin” being an abbreviation of “engine”, is a machine that is used to pull fibers from their seeds.

Those fibers can then be processed into various goods, while any undamaged material is used mostly for textiles like clothing.

Whitney’s machine worked like a sieve or strainer. The material was run through a wooden drum, which was embedded with a series of hooks. These hooks caught the fibers and dragged them through a mesh.

The mesh was too fine to let the seeds through, but the hooks pulled the fibers through easily. Smaller gins were cranked by hand. Larger ones were powered by a horse and, later, by a steam engine. Whitney’s hand-cranked machine could remove the seeds from 50 pounds of material in a single day.

The separated seeds can then be used to grow more or to produce cottonseed oil.

Growing a crop was very labor-intensive by itself. Separating the fiber from the cottonseed was even more difficult and time-consuming prior to the invention of the machine.

Continued Improvements

Further improvements and modifications were made to the mechanism over the years.

Fones McCarthy was granted a patent in 1840 for a roller version that was particularly effective at processing long-staple varieties. His mechanism was called a Smooth Cylinder Cotton-gin.

Additional improvements and features included:

- Steam power replaced animal power

- An automatic feeder was introduced

- A condenser was added to facilitate handling of the extruded clean material

- Indoor presses consolidated all processes into one place.

Finally, with what has become known as The Munger System Ginning Outfit, or system gin, all the ginning operation machinery was able to be fully integrated. This system ensured that the material would flow through the machines easily while using air to move material from mechanism to mechanism. This resulted in decreased production costs, increased efficiency, and higher quality fiber.

By the 1960s, many other advances had been made in ginning machinery, but the way in which cottonseed flowed through the machinery continued to be based on the Munger system.

Modern automated gins use multiple powered cleaning cylinders and saws and offer far higher productivity than their hand-powered precursors.

When Did it Become Widely Used?

Due to the radically reduced time it now took to separate the seeds from the fiber, Southern planters could increase their crops. As a result, by the mid-19th century, cotton had become America’s leading export.

In fact, it has been estimated that the United States supplied three-quarters of the global supply by 1861. It was now a tremendously profitable crop and made the American South the first global agricultural powerhouse.

How Did it Revolutionize the World?

It naturally followed that due to the far greater efficiency of the new design more crops could be grown, which meant more workers were needed. It is argued that Southern planters used this as justification to expand the practice of slavery. Certainly, more workers were needed, and plantation owners wanted cheap labor.

Slavery

There is an ongoing debate about the direct effect the mechanism had on slavery. Some of the early Founders believed that slavery would fade away in this country due to social reasons, the end of slave importation by 1808, and the unprofitability of slave-produced crops prior to the invention of Whitney’s machine.

Regardless, it cannot be denied that slavery was a key component of the industry. The material still needed to be picked by hand. This meant that many more workers were needed due to the new and hugely expanded ability to process as much material as could be grown and harvested.

The number of slaves rose proportionately along with the increase in production. There were approximately 700,000 slaves in 1790 and about 3.2 million in 1850. By 1860, black slave labor from the American South provided two-thirds of the world’s supply and up to 80% of the critical British market.

And it had a domino effect. The South continued to develop and depend on its economy from plantation-based agriculture, which encouraged the growth of the textile industry in the North and throughout the world.

Because of all this, the invention has often been cited as one of the indirect causes of the American Civil War.

Machine Tools

In addition, the huge increase in the supply of materials created a strong demand for textile machinery and improved machine designs. Metal parts replaced wooden ones, which led to the invention of machine tools in the early 19th century.

Mass Production

Eli Whitney was able to secure a contract in 1798 from the U.S. government to produce 10,000 muskets in two years. At the time, guns were still being crafted individually, so this was a huge leap.

Whitney promoted the idea of interchangeable parts, a novel idea at the time. He proposed manufacturing and using standardized or identical parts that could be assembled faster. This process would also make it easier to repair machines.

In this way, Whitney was instrumental in developing the American system of mass-production. And we know that mass production was one of the factors that helped usher in the age of the Industrial Revolution.

All this came from a better way to harvest material.

The Evolution

The development of the “gin” or harvester has come a long way.

Certi-Pik, USA has been providing the highest quality cotton harvester parts for today’s harvesters since 1988.

We offer a wide range of replacement parts to cover all your needs. We provide American and international customers with outstanding harvester parts for use with equipment manufactured by the industry’s leading makers of harvesters.

We also sell many specialty items and sheet metal parts to use in rebuilding your harvesting equipment.

As a member of the Better Business Bureau and with nearly a quarter of a century experience, you can be confident in buying from us. Call us at 712-752-8460 or visit us online to shop for your quality replacement parts.

Assuming that your cotton plants were introduced to the soil in mid-March or April, as they are south of the 36th parallel, most of those plants should be ready for harvesting by the end of July. Of course, this assumes that the weather has been relatively stable all summer and that the plants were not subjected to excessive amounts of rain. It matters a great deal where you live in the world when you ask, “When do you harvest cotton?”. In some areas of the world, the seasons are inverted from the way they are in the United States.

Some of the other factors which impact harvesting time are discussed below. Generally speaking, the time necessary for a cotton plant to reach full maturity, with no interruptions, is between 150 and 180 days, regardless of where you’re located. Of course, the specific months that the harvest will be ready is subject to the climate in whatever part of the world you live in. With a little cooperation from the weather and no severe disruption from pests, cotton can be harvested at the end of the 180 days and made into all the wonderful products that people love so much.

When Was the Cotton Planted?

Cotton is generally planted as a harvestable crop as soon as mid-March in the 13 American states, which are primary growers of cotton. By the time June rolls around, all plants have been started in the ground, and the staggered plant times will allow for continuous harvesting until the entire crop is in. Those states are mostly in the southern United States, where rainfall is somewhat plentiful in the springtime and is usually followed by a long period of hot and dry weather, which is also ideal for cotton growth.

In areas outside the U.S., the best time to plant the cotton seeds is right before a somewhat wet season so that the plants can get plenty of water. Then, of course, the plants will need the warmth that will allow the plants to develop and mature properly. If you’re planting cotton seeds indoors, the best time to plant is approximately four weeks prior to the last anticipated date of outdoor frost. As with outdoor planted cotton, the answer to when to harvest cotton will be somewhere around 180 days after planting.

Assess the Health of the Plant

The health of cotton plants can be affected by several factors, and many of these contribute significant stress to the plants. Some of the most common stressors are moisture, pest attacks, temperature, and nutrition. When summer temperatures soar past 95 degrees Fahrenheit, it begins to really affect the cotton plant, and leaf production suffers as well as the creation of carbohydrates. When carbohydrate levels drop, the plant has insufficient sugar levels to satisfy all its needs, and that generally leads to fewer bolls on the plant, as well as less fiber content in each of the seeds.

When night-time temperatures remain high instead of dropping off to a more appropriate 68 degrees, the temperature can have a double whammy on hurting the delicate plants. Moisture also comes into play, because when there is excessive humidity present, it does not allow for plant moisture to evaporate, and for cooling all the components of the plant. If there is too much rainfall present in the summertime, that can have the effect of drowning out the still immature root system of the cotton plants and hinder its growth.

There are two major pests that love to feast on cotton – the boll weevil and the pink bollworm. Boll weevils like to consume the cotton seeds, and its feces has a profoundly negative impact on cotton lint. It severely attacks bolls and flowers, and for that reason, there is a program of eradication underway in the major cotton-growing states. The bolls and flowers are also under siege by the pink bollworm, which generally appears on the plants as a brown and gray colored moth. Its eggs are laid under the calyx of bolls, which are in the developmental stage, and when they hatch, they immediately begin consuming the plant.

Know Your Climate

Cotton is a plant that is native to Central America and the region around the Caribbean. Still, it’s also considered a perennial by the US Department of Agriculture in zones eight through 11. When planted as a harvestable crop, cotton needs a long stretch of very warm weather with periodic irrigation. After that, it also needs relatively dry weather so that the fluffy white cotton balls can become adequately ripened.

When the temperature in any climatic area dips below 60°F, it will be necessary to provide additional heat somehow or to take the plants indoors where heating can be regulated. If you live in an area where springtime is long and autumn advances early, you may have to grow your cotton plants in pots, which can be taken indoors. If you start your plants indoors, you’ll have to wait until you have consistently warm weather before taking the young plants outdoors.

You probably will not be surprised to learn that cotton is the most-used natural fiber in the entire world. This is largely because of the importance cotton has in the textile industry. In 2016 alone, the global production of cotton has been around 103.17 million bales, with India, China and the United States accounting for more than half of that total worldwide production volume. The total global supply of cotton, including all of the cotton currently being stored, stands at somewhere around 238.57 million bales.

The United States has long been known for its thriving cotton industry, and that continues to be the case today. America is the world’s leading exporter of cotton, sending some 10.5 million bales around the world this year. Most of the cotton that the United States harvested actually was sent out to other nations. Other leading exporters this year were India, Brazil and Australia, while leading importers including Bangladesh, China and Vietnam, all of which have large-scale cotton clothing industries.

Here in the United States, approximately 8.6 million acres of land planted with cotton was harvested last year. The total production value of this cotton was nearly $3.86 billion.

It’s the southern states that produce by far the most cotton in the nation. Texas was the leading cotton producing state in the nation last year at 5.8 million bales, followed closely by Georgia, Mississippi and North Carolina, in that order.

Long-term trends

For most of the first decade of the 21st century, cotton prices remained fairly stable, averaging 60 to 70 U.S. cents per pound on the international market. Prices achieved their highest point ever in 2011 at approximately 156 cents per pound, but prices have since rapidly decreased back to slightly over their previous levels. Of course, a major reason for the spike was the economic recession suffered by the United States and many other countries around the world at the turn of this decade.

Currently, the amount of cotton production in the United States is lagging behind the averages for most of the past decade and a half. The early- to mid-2000s saw cotton production levels regularly exceed 20 million barrels annually. In 2015, however, there were only about 13 million bales produced.

Still, despite the lower-than-average figures for recent times, the industry is very stable compared to other periods in American history. In the early 1920s, for example, cotton and tobacco prices collapsed due to overproduction and an ensuing boll weevil infestation that wiped out massive plantings of the crop. Since mechanical pickers became more affordable in the 1950s, however, and agricultural practices have increased, these types of cotton crises have been practically eliminated on a national level.

We always find it interesting to look at the state of the cotton industry here in the United States, because it is so deeply woven into the fabric (no pun intended) of American culture. For more information about the equipment we have to offer cotton farmers, including cotton picker spindles, contact the experts at Certi-Pik, USA today.

Ensuring your cotton harvest will be a successful one requires more than cotton picker parts in good condition. Your preparation must be as effective as possible, as any difficulties that your cotton may experience in its early stages of growth will prevent it from continued success throughout the growing season.

Before the season starts, read through the following tips and make a plan based on your expectations for your harvest:

- Consider updating your row spacing: If your rows are spaced 38 to 40 inches wide, which is considered a fairly typical spacing, consider changing to a smaller pattern of 15 to 30 inches. This switch may prompt cotton to grow sooner and allow for more light if you find that your plants frequently tend to grow on the smaller side. However, determining whether to update your row spacing is not a decision that should be made hastily. It’s possible that such a change may require the purchase of new equipment, so be sure that changing the spacing of your rows is the most logical option for you and your harvesting needs.

- Treat your plants with fungicides: Experts suggest that you should treat the plants that are part of your cotton harvest with at least two fungicides. Many fungicides protect against only one type of disease, and plants do not absorb all fungicide products the same way. At the time of planting, use an insecticide product designed to offer long-term results. Then, early in the season, be sure to observe your plants for any instances of mites or insects. If your cotton plants seem to be consistently growing, they may be able to resist some negative effects caused by pests as the season goes on.

- Experiment with different plant varieties: If you’re seeking a high yield, it’s important to note that the variety of your plants and the quality of the seeds play a role in your crop’s success early in the season, and in the general health of your plants. As a result, be sure not to make plans to plant solely the varieties that produced the highest yields in a single season or year. Instead, compare the averages of these plants over multiple seasons. You also want to ensure that at least some of the varieties you’re planting can resist, or at least have some tolerance to, factors such as plant diseases, various pests, temperature and moisture. However, you should plant new-to-you varieties only on some of your land. Experts recommend that new varieties should make up no more than 10 percent of your harvest.

Now that you’re ready to perform the steps to plan for and carry out a successful harvest, take the time to order any cotton picker parts that you need before the season starts. At Certi-Pik, USA, we offer replacement parts for John Deere, Case IH and CNH cotton harvesters and are committed to providing high quality customer service. We treat every order as a rush order. Contact us today at 888-CERTIPIK (237-8474)!